We’ll be with you every step of the way.

PLAN FOR SUCCESS

The planning phase of any project holds utmost significance as it sets the foundation for future decisions and outcomes. At Kindred Spirits, our primary objective is to collaborate with you throughout this crucial phase, ensuring clarity and eliminating uncertainties every step of the way.

Our primary objective is to collaborate with you.

The spirits you will produce

Choosing which spirits to produce has a major impact on distillery planning. For instance, crafting vodka from scratch demands different equipment than focusing on rum or whiskey. Conversely, if your aim is to blend pre-made spirits, your equipment requirements would also vary significantly. There's nothing more disheartening than realizing your equipment can't produce the spirit you're passionate about. That's why we prioritize helping you make the right equipment choices from the start. This saves you money and frustration in the long run.

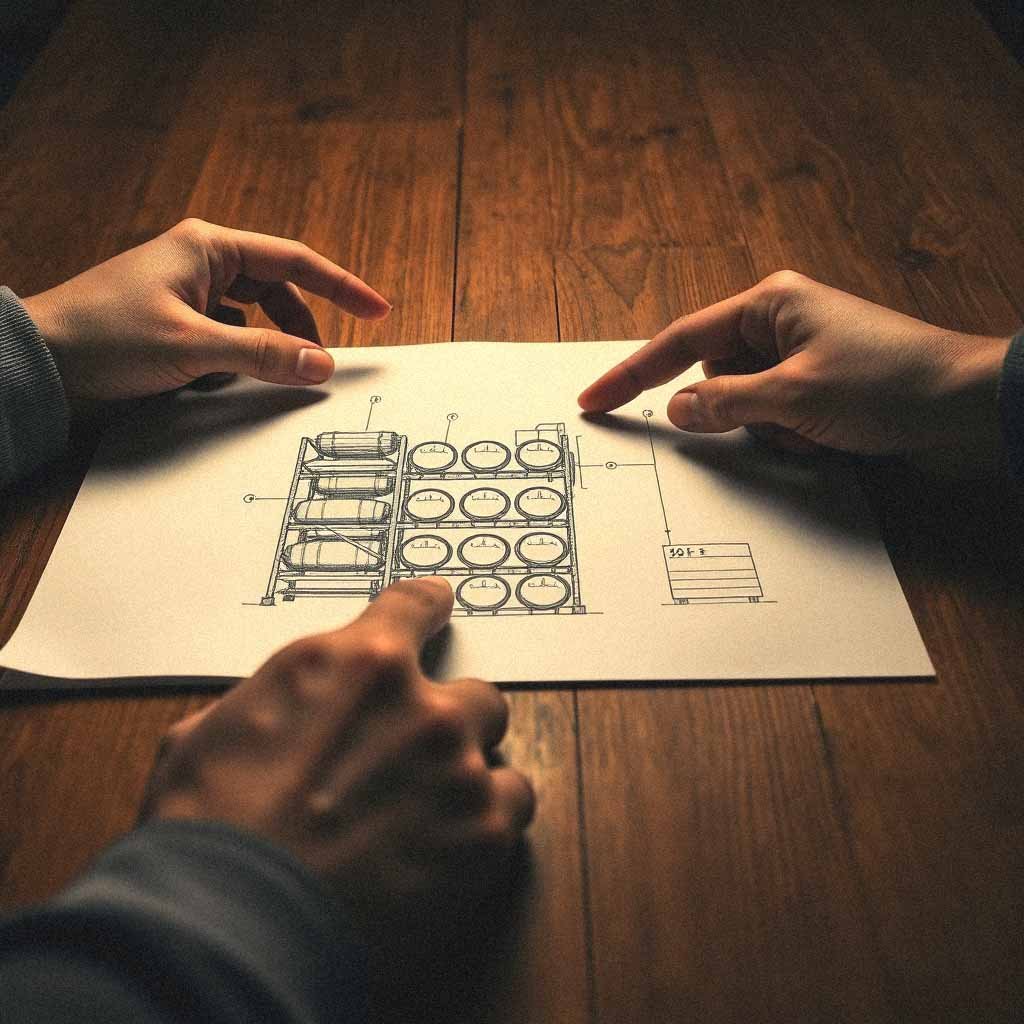

Design Layout

The layout of your distillery plays a crucial role in its efficiency and safety. Strategically placing equipment throughout your workspace ensures optimal functionality and minimizes hazards. Given that most distillery equipment is large and permanently installed, any redesigns or adjustments post-setup can be costly, particularly steam piping installations. Therefore, careful planning of your building layout is essential to avoid unnecessary expenses and delays.

"A place for everything, and everything in its place" is a mantra that holds true for distilleries. A well-organized space not only enhances efficiency but also contributes to a clean and appealing environment, ideal for tours and future expansion endeavors. Our seasoned designers collaborate with you to create a layout that prioritizes safety, functionality, and aesthetics. Moreover, we anticipate future growth and ensure that the design accommodates the increasing demand for your product seamlessly.

Equipment selection

During the planning phase, critical decisions are made regarding equipment sizing, building selection, and layout design to meet both present and future needs. Thoughtful selection of key equipment such as boilers, stills, mash tuns, finishing tanks, and fermenters can result in substantial cost savings and propel your project forward. Opting for improperly sized equipment can lead to inefficiencies, increased operational costs, and disrupted workflow, ultimately consuming valuable time.

Unfortunately, many distilleries fall prey to the allure of seemingly attractive deals on equipment, only to realize later the significant hidden costs involved. A prime example is the sizing of boilers, often available at discounted rates online. Choosing a boiler that is too small restricts the efficient utilization of distillery equipment, while selecting one that is too large incurs unnecessary expenses in terms of equipment, installation, and maintenance.

When selecting equipment, factors such as main fuel, working pressure, steam input and output, efficiency, electrical requirements, local codes, and overall size must be carefully considered to avoid squandering resources. Our consultants are dedicated to guiding you through these considerations, ensuring that your hard-earned funds are invested wisely.

Ready to get started?

We’re here to help.

Don't go it alone, schedule a free consultation to see how we can take your ideas from just a dream to award-winning.